About Our MI Cable Assemblies

At MICC, we understand that every project is unique. That’s why we offer high-quality cable assemblies to help you achieve optimal performance. Discover what our cable assemblies have to offer.

Material Specifications

- Mineral insulated cable is made of high-conductivity copper ASTM B4 or B5.

- The insulation is compressed magnesium oxide powder.

- The seamless phosphorous-deoxidized copper sheath can withstand a maximum continuous operating temperature of 250ºC.

- The cable has a working voltage of 0-300 volts AC/DC and 0-600 volts AC/DC.

- The factory test voltage is 1500 volts RMS (300-volt cable) and 2500 volts RMS (600-volt cable).

- The power factor is 0.1%.

- The dielectric constant (SIC) is 3.7, and the dielectric strength is 70 volts/ml at 475ºC.

Note: For data on Alloy 825 outer sheath with solid nickel conductors, please contact our sales department.

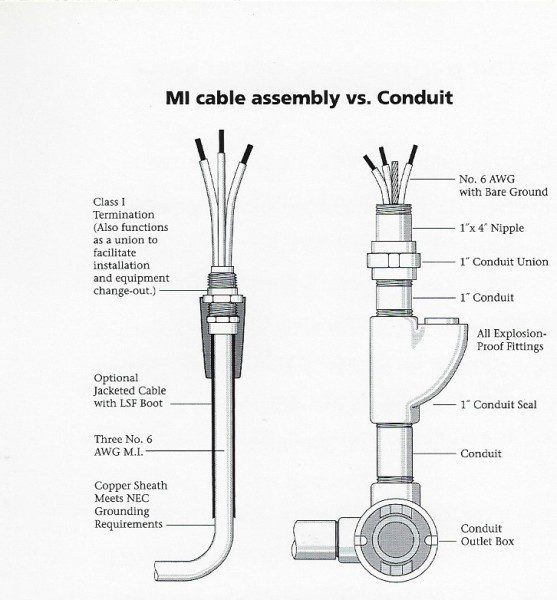

Mineral Insulated Cable vs. Conduit

When it comes to choosing between mineral insulated cable and conduit, the former offers a more reliable and cost-effective solution. Mineral insulated cable eliminates the need for additional materials such as pull boxes, unions, grounding wires, conduit seals, and other fittings. It is pressure tested to 2000 psi and blocks the passage of vapors, gases, liquids, and flames, confining any exploding gases to their immediate area.

With conduit, seals must be placed within 18″ of the arcing device or instrument to be connected to the conduit system. If a conduit seal fails, gas or liquids can migrate freely, which is why some companies require single or double conduit seals in hazardous areas to be annually x-rayed and inspected. Choose mineral insulated cable for superior performance and peace of mind.

What Our Cable Assemblies Offer

Fire and Heat Resistance

MI cable is the ultimate fire-resistant electrical cable system. Its inorganic construction makes it capable of withstanding high temperatures and heavy current overloads without emitting smoke or toxic substances. It can easily withstand temperatures up to 1982ºF, 1083ºC, which is equal to the melting point of copper. Unlike standard conduit and wire, which failed at 425ºF in a third-party test, MI cable allows no flame propagation, making it the safest choice for critical and essential circuit protection.

Temperature Stability

Say goodbye to the risk of rust and corrosion buildup in your electrical devices due to temperature fluctuations. Mineral insulated cable assemblies are the perfect solution for harsh environments. Unlike exposed conduits, which can accumulate moisture and rust, MI cable assemblies are completely moisture-resistant and solid.

This eliminates the risk of rust and corrosion buildup, which can block the conduit drain and damage the instrument or electrical device. MI cable assemblies are ideal for industrial applications such as power wiring to motors in LNG tanks, freezer rooms, and instrument connections in harsh climates such as Alaska and Canada.

Water Resistance

Water resistance is a key feature of MI cable assemblies, which are used in various industrial applications. For example, they are approved by the US Coast Guard and used to connect warning beacons on marine vessels. Additionally, MI cable assemblies are ideal for light-fitting connections in oil tanks, where they can withstand even the harshest of climatic conditions.

Radiation Resistance

Magnesium oxide, the insulation in mineral insulated cable, offers exceptional radiation resistance compared to other materials. This makes MICC cable assemblies an ideal choice for applications in nuclear power plants. The compacted magnesium oxide insulation and copper sheath ensure reliable performance even in high-radiation environments.